High Frequency Press - Solid Edge Glue

Product added to inquiry box

Continue shopping

Proceed

|

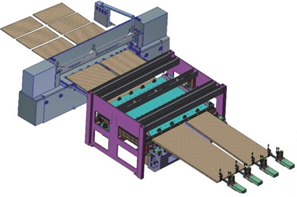

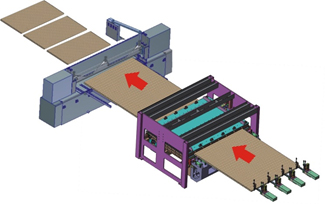

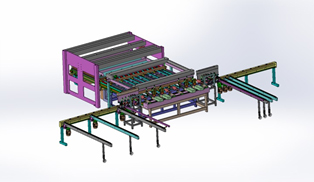

| 1. Equipped with one set of auto loader 2. Equipped with one set of auto side gluer with two component mix glue function 3. Robotic arm pusher 4. HF continuously edge glue 5. Glue curing cycle time for 2.5M width, 1.6M length panel is around 1min. 6. Electricity cost USD 0.1 for one stock 7. High speed edge glue press, no workforce needed ,reduce workers up to 8 persons |

|

| 1. Continuous edge gluing 2. Docking with panel saw for cutting optimization 3. Solid wood edge glue, short material edge glue 4. High speed production |

|

| 1. Continuous edge gluing 2. Continuous edge gluing for finger jointed panel 3. Docking with panel saw for optimized cutting. |

|

| 1. Auto loader 2. Work ranging from 400mm to 4500mm for loading 3. One by one loading, automatic alignment before loading |

|

| 1. Fully automatic single-side edge gluer, 2. Glue Mixer Tank for PVAC and hardener 3. Glue Tank for one component glue. 4. Roller gluing to make sure each piece in even spreading 5. Six sets of automatic feeding roller for stable loading. 6. Speed control from 3 meter to 20 meter/per minutes. |

|

| 1. Robotic arm pusher 2. Servo control system for the length of material push settings 3. Simulate as human hand, push-in 4. Two sets of robotic-arm results in continuous feeding for fast loading |

|

| 1. Independent islanded Controller 2. Digital control, all working data will be stored in the HMI 3. Measuring heating time automatically to prevent uneven heating mistakes from manual input. 4. Docking with upstream and downstream fabrication machines to achieve full intelligent production. |

|

| 1. Versatile deployments, full customized design. 2. Auto loader applied to left and right both side for bilateral feeding |

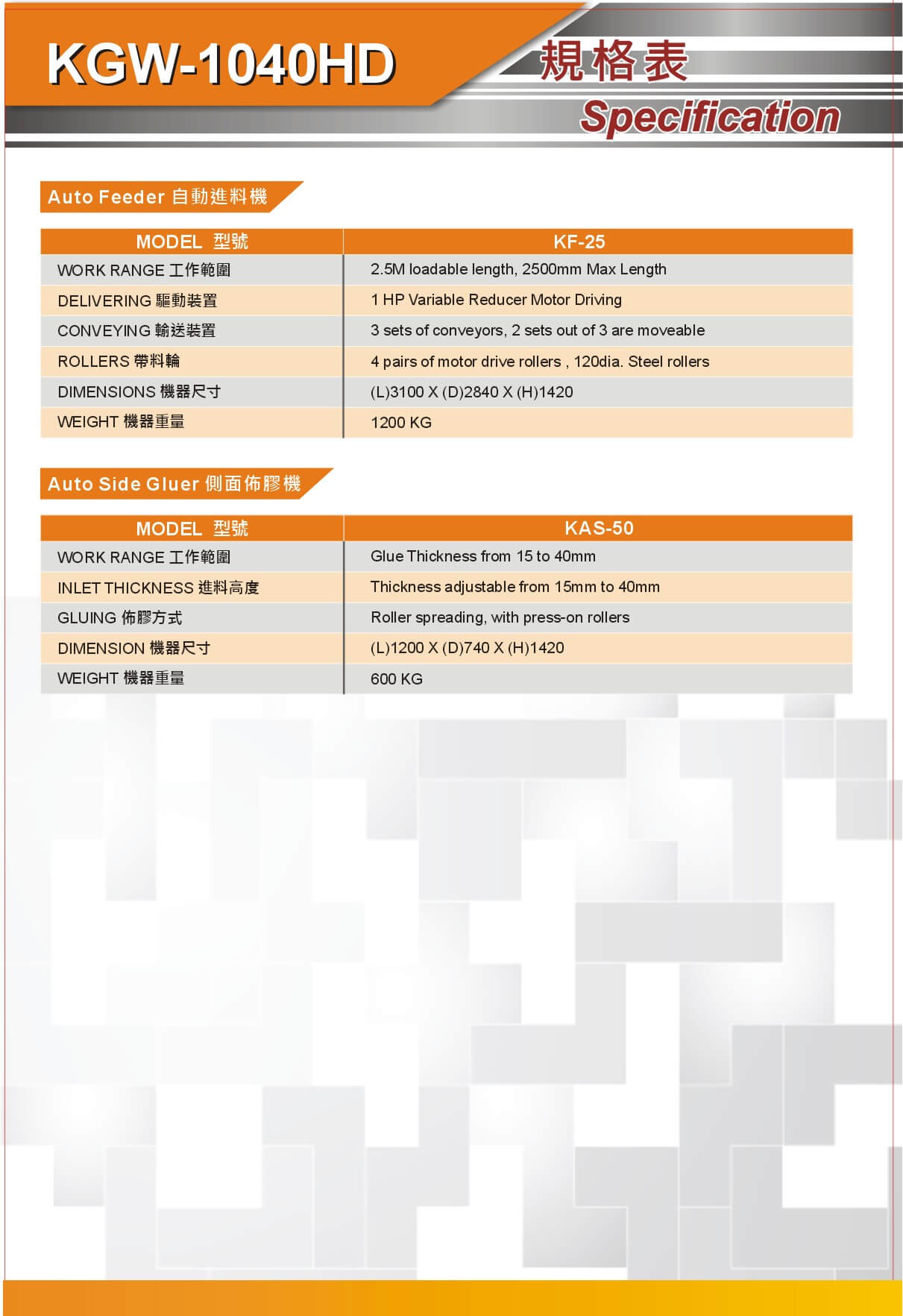

| KAS-50 |

|

| KGW-402D |

|

|

| YouTube |

| Youku |